Sustainable Solutions for the CNC & Metalwork Sector

With the range of Bio Circle Solutions and Equipment options, it’s easy to clean parts in the CNC and Metalwork sector sustainably.

For more than 30 years Bio-Circle has been using a combination of technology, chemistry, biology and service to optimise our customer cleaning processes.

Bio-Circle’s cleaning systems have a lower environmental impact compared to traditional cleaning products, are free from harsh chemicals and reduce costs across many industries.

Offering systems and solutions from manual parts cleaning to automatic parts cleaning, with low pressure or high pressure, or a variable pressure system, we have the solutions to meet your requirements.

Our high performance products are:

- Efficient

- Environmentally friendly

- Compatible with oil separators, tested in accordance with ÖNORM B5105

BIO CIRCLE GT Manual Parts Wash Systems

The BIO-CIRCLE GT parts washers are true specialists in cleaning in the CNC and metalwork sector. Metalworking oils and emulsions are removed reliably. Filter mats and other metal working machine parts are cleaned optimally during maintenance. They clean without solvents, protecting employees and the environment from highly volatile vapours, (VOC’s). Working together with the range of BIO CIRCLE solutions the BIO-CIRCLE parts washer removes these contaminations in an eco-friendly way and helps meet the high requirements of the Solvents Regulation.

Some of the benefits of use in the CNC and Metalwork sector include:

- VOC-free parts cleaning

- Reduced waste

- Bioremediation process

- Running temperature 40°c

- Cleans parts quickly and efficiently

LOOKING FOR AN AUTOMATIC SYSTEM, NOT A PROBLEM.

ULTRASONIC SYSTEMS – SINGLE & MULTI-FREQUENCY DEVICES

Ultrasonic cleaning is a very effective and gentle cleaning method commonly used in the CNC and Metalworking sector. The ultrasound generates millions of minute vacuum bubbles in the cleaning medium that generates high pressure when they collapse. Even hard cases with rigid surfaces and complex geometries are cleaned effectively with ultrasonic waves. Extremely persistent contaminations, such as dried-on oils and greases, paints and varnishes or rust, will be dissolved with the aid of the appropriate cleaner, even from the tiniest of bores, material pores, and Orifices.

Available Units

- BC-Sonic 37

- Available in 8 different device sizes.

- 37 kHz ultrasonic power

- For all common applications

- Capacities from 2.75 L to 90 L

- BC-Sonic 25/45

- Available in 7 different device sizes (22 L to 215 L) and equipped with different frequencies:

- 25 kHz ultrasonic power — for rough pre-cleaning

- 45 kHz ultrasonic power — for gentle final cleaning

- Dynamic function — by switching phase shift and additional pulse on and off cleaning times are shortened and very persistent contaminations are dissolved

- Hinged lid for noise insulation and evaporation reduction as an optional extra

- Castors instead Of feet

The innovative optimization of ultrasonic cleaning

The Bio-Circle STAR US cleaners optimize the cleaning performance of the ultrasound. The selected surfactants and active ingredients are constantly active in strong intensive cleaning (25 kHz) as well as in fi ne cleaning (45 kHz). The cleaners are water-based, VOC-free or VOC-reduced, highly concentrated and demulsifying.

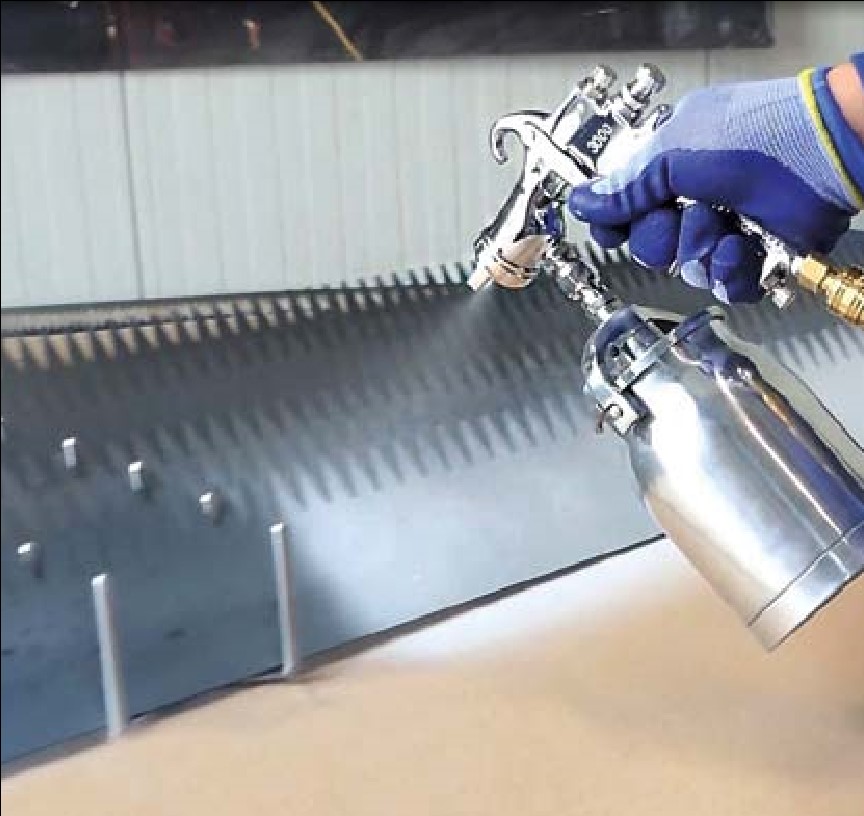

E-WELD SHIELD – For Plasma & Laser Cutting Machines

In plasma- or laser-cutting processes the formation and build-up of slag is a big issue. The maintenance of the bars is time-consuming, and often requires costly replacement or repair. The build-up of slag on the carrier material of the metal sheets to be processed (bars) creates an uneven surface that has an adverse effect on the quality of the cut outs. The slag has to be removed in a laborious process, or the bars have to be replaced. This is where E-Weld Shield comes in. A simple application covering the bars is all that is required to realise the benefits of E-Weld shield:

- Quality assurance thanks to the even support provided by the bars

- Easy removal of slag

- Extended bar life

- Shorter setup times

- Time & cost savings at increased quality assurance

WELDING – RELEASE AGENTS FOR WELDING

Optimal separating effect on weld spatter

Spray it on. Weld. Wipe it off . Finished.

The anti-spatter sprays prevent weld spatter from burning in during MIG/MAG welding and laser- and plasma cutting. Trouble-free zinc coating, powder coating and varnishing after welding can be done anywhere and anytime, because the nature-identical ingredients are silicone- and oil-free! In this context, we have been granted approvals issued by Herning Zinc Coating, Volkswagen AG, SLT Laser Technology et al.

Just some of the products available for the Welding Sector. Just ask one of our representatives for more information on the range of products and systems available.

SURFOX – THE ALTERNATIVE TO PICKLING PASTES!

Electro-chemical weld seam cleaning for stainless steel and co.

SURFOX is the alternative to pickling pastes. The patented weld seam cleaning device is an effective method of removing heat tinting after welding from TIG-, MIG-, and spot welds on stainless steel and aluminium. It promotes the formation of a uniform and durable passive chromium oxide layer which protects the stainless steel from further corrosion. An output regulator facilitates a perfect finish even on sensitive surfaces. Oxide and smoke residues are effectively removed from aluminium welds. Just ask one of our representatives for more information on the range of SURFOX systems.

LUBRICANTS

Smooth operations

Lubricants reduce friction between parts moving against or on one another. They are indispensable in the maintenance and care of tools and machines; moreover, they provide protection from high temperatures.

Lubricants make an essential contribution to machine productivity and hence to the entire manufacturing process.

Our lubricants are ready for use and provide temporary corrosion protection. They are all solvent-free and (almost all) non-labelled – environmentally compatible and safe to use including Aqua-Form, Food Tech Oil, Anti-Seize, Metal Free Anti-Seize, Cutting Coolant milky, and High-Performance Cutting Oil.