Sustainable Solutions for the Transportation Sector, covering all aspects of transport including shipping, aviation, trucks, and railways.

It’s easy to clean and maintain parts and equipment sustainably.

For more than 30 years Bio-Circle has been using a combination of technology, chemistry, biology and service to optimise our customer cleaning processes.

Bio-Circle’s cleaning systems have a lower environmental impact compared to traditional cleaning products, are free from harsh chemicals and reduce costs across many industries.

Our high performance products are:

- Efficient

- Environmentally friendly

- Compliant with wash down legislation

BIO CIRCLE GT MAXI

- VOC-free parts cleaning

- pH neutral

- Zero waste

- Bioremediation process

- Running temperature 40°c

- Cleans parts and equipment quickly and efficiently

LOOKING FOR AN AUTOMATIC SYSTEM, NOT A PROBLEM.

Efficient Cleaning of Bearings and Heavily Contaminated Parts.

CB 100 is the cleaner that benefits from the power of Nature. The water-based cleaner with its pleasant scent is produced from renewable raw materials derived from recycled products. These natural active substances provide the cleaner with its strong dissolving powers. The surface remains unaffected, and the original finish is restored. Used together with our automatic Hot Wash systems parts can be effortlessly cleaned.

BIO-CIRCLE HP AND BIO-CIRCLE HP VIGO

The power of high-pressure cleaning

Two closed washing chambers, with the BIO-CIRCLE HP simultaneously serving as a parts washer with brush (fulfilling this function with the lid open as well as closed). Both washing chambers operate with the power of high-pressure cleaning. They are recyclable and remove oils and greases from heavily contaminated steel-, stainless-steel-, plastics- and other parts with complex geometries.

Their only mission: Making work easier for the user! For the components will be beautifully clean and shiny, and the workflow is simple, fast, and safe (provided the recommended cleaners are used).

THE CLEAN BOX MAX & FLEX

- UV resistant/double wall protection

- Can be located above or below ground

- Fully recycles water & solution (CB100)

- Tank holds 220ltr water & 130 ltr CB100 (Flex)

- 12 weeks usage saves min 5,700ltr water/ min pa 23,000ltr against traditional pressure wash systems

- 2-4 bar pressure

- Controlled water usage and control of flow

- Low environmental impact

BIO RUST

The Bio Rust solution is an eco friendly, pH neutral, solution that quickly and effectively removes rust. Perfect for cleaning old impregnated rust, through to newly developed spot rust on parts and equipment. The key benefits of the BIO RUST product includes:

- Non caustic, non toxic

- Non corrosive

- Water based and VOC Free

- Removes rust without surface damage and other materials

- pH Neutral

- Straight forward immersion process

- Label free under the CLP Regulation

- Free from halides

- Low foaming

- Extends the life of parts and tools

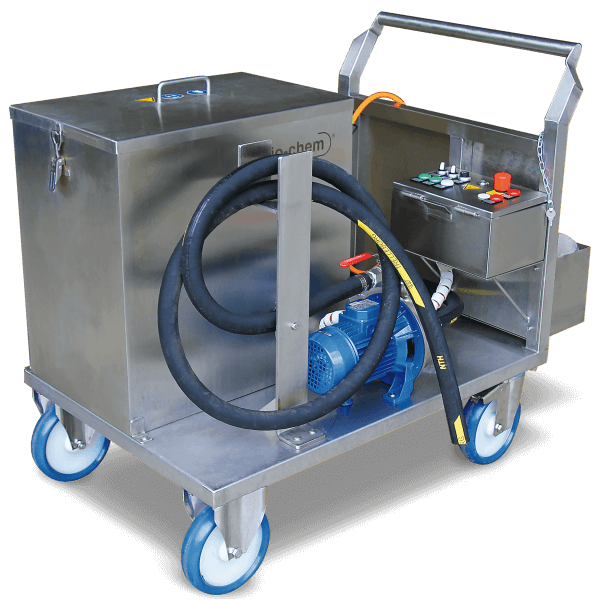

BIO-CIRCLE Pipe and tank cleaning device

Cleaning system for pipes, tanks and heat exchangers

Completely made of stainless steel, the BIO-CIRCLE pipe and tank cleaning device has been designed especially for the cleaning and fl ushing of contaminated pipes, wastewater tanks, freshwater pipes and tanks, heat exchangers and coolers. With the bio-chem Power Cleaner DB cleaning fl uid contaminations such as urine scale, limescale and corrosion can be removed effi ciently, benefi ting from a simultaneous antibacterial effect. The bio-chem Smoke Resin Remover DB cleaning fl uid can be relied on to remove greases, oils and carbonized oil.

- Cold and hot operation (thermostat adjustable up to 90 °C – factory-set at an optimum of 60 °C)

- Stainless steel float switch prevents pump and heating from dry-running

- Hose tray with drain for easy emptying

- Mobile – the device has been mounted on a trolley and can thus be taken directly to the application site, in case of the RWR 500 DB also by means of a guide rail using a forklift truck

Power Cleaner DB

Powerful, water-based acidic cleaner

The Power Cleaner DB is a phosphate and hydrochloric acid free water-based intensive cleaner, highly concentrated, which can be diluted with water to 1:40. Used in many application both stand alone or together with the RWR pipe and waterway cleaning systems the Power Cleaner DB solution dissolves cement and limescale residues, urine scale, moss and algae, rust as well as films from brass and copper, water stains and black fungus stains, with simultaneous germ reduction and disinfection.

UNO S V und UNO X

Efficient cleaning of bogies and electric motors

UNO S V and UNO X are viscous, foaming aqueous solvent-free cleaners for removing environmental dirt, dust, oil, grease and soot from bogies, electric motors and similarly contaminated steel parts. Both cleaners should be used highly concentrated or diluted up to 1:10 with water. We recommend using a foam gun or foaming device when applying both UNO S V and UNO X. Since the cleaners are viscous and foaming, they adhere very well to vertical surfaces. This grants an advanced cleaning result, while keeping the usage of cleaners, wastewater and overall costs low.