Sustainable Solutions for the Renewable Energy Sector

With the range of Bio Circle Solutions and Equipment options, it’s easy to clean parts in the renewable energy sector sustainably.

For more than 30 years Bio-Circle has been using a combination of technology, chemistry, biology and service to optimise our customer cleaning processes.

Bio-Circle’s cleaning systems have a lower environmental impact compared to traditional cleaning products, are free from harsh chemicals and reduce costs across many industries.

Offering systems and solutions from manual parts cleaning to automatic parts cleaning, with low pressure or high pressure, or a variable pressure system, we have the solutions to meet your requirements.

Our high performance products are:

- Efficient

- Environmentally friendly

- Compatible with oil separators, tested in accordance with ÖNORM B5105

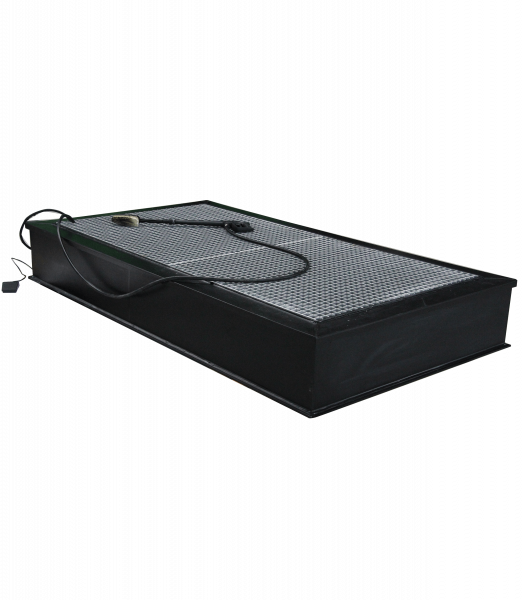

BIO CIRCLE GT Manual Parts Wash Systems

Frequently oil contaminations on components and gear- boxes are cleaned with brake cleaners. Apart from the costs, the issues of environmental protection and, above all, explosion hazards determine the decisions. The BIO-CIRCLE parts washer removes these contaminations in an eco-friendly way and helps meet the high requirements of the Solvents Regulation.

The Bio-Circle GT environmental parts cleaners provide sustainable parts cleaning, with zero water waste and without washing pollutants down the drain. Working together with the range of Bio Circle solutions the Bio Circle system cleans and removes grease and oil contamination. Some of the benefits of use in the Renewable Energy sector include:

- VOC-free parts cleaning

- Reduced waste

- Bioremediation process

- Running temperature 40°c

- Cleans parts quickly and efficiently

CLEAN BOX FLEX

- UV resistant/double wall protection

- Can be located above or below ground

- Fully recycles water & solution (CB100)

- Tank holds 220ltr water & 130 ltr CB100

- 2-4 bar pressure

- Controlled water usage and control of flow

- Low environmental impact

CB100

The CB100 solution is a VOC free water based cleaning solution for stubborn contaminations. Based on renewable raw materials, increasing occupational health and safety, reducing operating costs, and the sustainable ingredients make the CB100 user friendly and environmentally compatible. A versatile solution that can be used in a manual spray out in the field and within a range of manual and automatic cleaning systems. Some of the key benefits of the CB100 product includes:

- Water based and VOC Free

- Nature Boost cleaning

- Low foaming

- Can be used as a manual spray, dip tank, ultrasonic, and in an automatic cleaning system

- Label free under the CLP Regulation

- Phosphate and solvent free

GS200

The GS200 solution is a VOC Reduced cleaning solution for very strong contaminations. GS 200 removes cracking, persistent greases, anti-rust waxes, bitumen, polymers, adhesive residues, sealing compounds (also silicone), rubber and many more in a natural way. The extremely economical cleaner operates on the basis of renewable raw materials and is the effective alternative to traditional solvent cleaners. Some of the key benefits of the GS200 product includes:

- Non-Flammable

- Nature Boost cleaning

- High Flashpoint (~ 100 °C/212 °F) enhances safety during application

- Can be used as a manual spray, dip tank, or in the Bio Circle Vario SL Compact manual cleaning system

- Label free under the CLP Regulation